Force measurement is vital to ensure compliance with performance and reliability standards. To ensure quality, reliability and safety in product design, compression testing must be implemented in a wide variety of industries. Shown here is a syringe compression application. This type of plate allows air to escape through slots during compression.Ī typical compression testing system consists of a test frame, force gage/load cell, and application-specific fixtures. In a top load test, it is important to use a vented compression plate. The test stand is fitted with a load cell, an indicator, and a compression plate. The water bottle is secured at the base of a single or double-column force test stand. An example of such testing is measuring the top load on a five-gallon water cooler bottle. A top-load test typically involves applying a downward compression force to measure the product’s resistance to crushing or a compressive load until it deforms or collapses. PET (polyethylene teraphthalate) bottles, containers, cans, and cartons are required to resist compressive forces that could otherwise cause leakage or breakage. Top load testing is important in the packaging, beverage, and consumer goods industries.

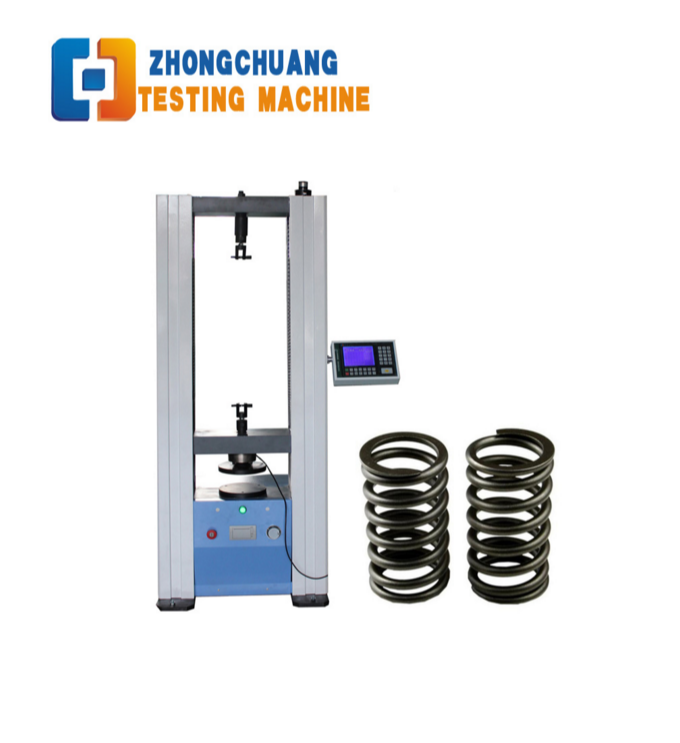

SPRING COMPRESSION TESTER MANUAL

These tests can be completed with a force gage, probe, and manual or motorized test stand.

SPRING COMPRESSION TESTER SKIN

The force at which the skin breaks is used to quantify the ripeness. A probe can be inserted through the skin of a fruit or vegetable at a controlled rate of speed. Fruit Ripeness Testingįruit and vegetable ripeness might not be the first thing you think of when considering compression testing, but it is an important test within the agricultural industry. A typical spring tester can be comprised of a manual or motorized force test stand, force gage (or indicator in conjunction with a load cell), compression plates, and data collection software. Several parameters are often measured including spring rate, spring load, load at displacement, and displacement at load. Compression spring manufacturers must verify the characteristics of their springs. A force can be applied to push a spring so that it undergoes a displacement from its unstrained length. Pens, tire gages, staples, mattress, and electrical contacts are among the many objects that can incorporate the use of springs. Springs are common objects that have many applications. Data is transmitted to a computer or tablet for further analysis. An indicator and load cell are implemented as a means to measure the force. One specific example utilizes a single or double-column force test stand to compress concrete pellets with a compression plate. Testing the compressive strength of concrete aggregate pellets assists in developing the proper water/cement material ratio. Determining the strength of the aggregate is important because it is a necessary component that defines the concrete’s thermal and elastic properties. Concrete is a mix of cement material, aggregate, and water. It is used for roadways, bridges, houses, commercial buildings, and even kitchen countertops. Concrete is an important building material that has been in use since Roman times. We often take for granted the strength of the sidewalk that one stands upon. Compression Test APPLICATIONS: Concrete Aggregate Compression Strength

Data can be used to facilitate the design process, evaluate batch quality, determine consistency, reduce manufacturing costs, and establish compliance with industry standards. Compression tests ensure that products are safe and manufactured to the highest quality standards.

0 kommentar(er)

0 kommentar(er)